Manufacturing of machinery and mechanical equipment in Trieste

Customized mechanical solutions for industrial applications in Trieste

There manufacturing of machinery and mechanical equipment in Trieste represents the operational core of the Officine Meccaniche Vidali, a company specialized in design and construction of technical solutions intended for industrial uses and professional. The company operates through a structured process that integrates preliminary analysis, design development, and quality control, ensuring that the products fully meet the client's functional needs. Each product is the result of an engineering process that combines consolidated experience, certified materials and production technologies suited to the creation of unique pieces and lots intended for highly specific sectors.

From the outset, the company's approach has been based on project customization, with the goal of developing machinery capable of performing precise functions within complex operating environments. A dedicated technical study allows for a thorough assessment of the application, operating conditions, and necessary structural requirements, thus ensuring a design consistent with the required production standards. The availability of a comprehensive and up-to-date machinery fleet allows for effective management of every production phase, from cutting to machining, up to the final construction of the equipment.

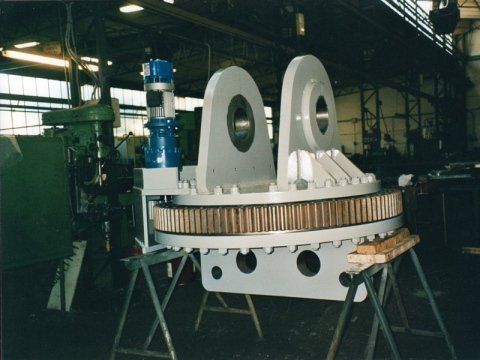

Lifting and transport machines for specific uses

- Design and construction of lifting and transport systems for specific uses;

- platforms, cranes, special lifting and transport machines

Learn more

Mechanical production for specific technical uses

Officine Meccaniche Vidali develops mechanical products for industrial, naval, and scientific applications, offering solutions designed for contexts requiring precision, reliability, and long-term durability. Their activities include the design of complex machines, the production of special components, and the construction of electro-welded structures, with constant monitoring throughout the entire production cycle.

Lifting and transport machines for specific uses

Lifting and transport machinery represents a significant portion of production activities. The design includes platforms, cranes, and handling systems built to meet specific operational functions. Each structure is developed through technical assessments related to operating conditions, load capacity, and operational safety. The goal is to provide equipment that ensures operational continuity and stability even in particularly demanding work situations.

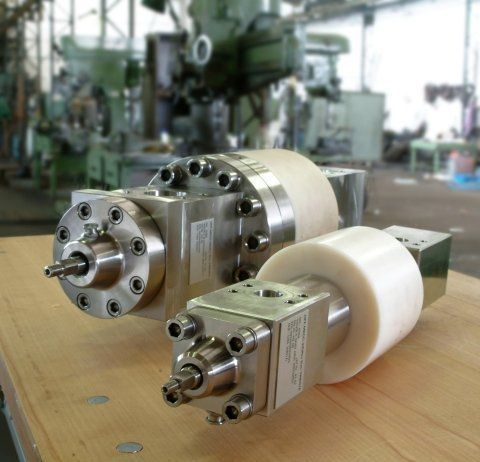

Winches and Hydraulic Transmissions

- Oceanographic winches for dredging, deep-sea coring, and lowering and towing scientific instruments (side-scan sonar/sub-bottom profilers, box corers, grabs, dredges, water sampling equipment, Niskin bottles, rosettes, nets, etc.). Lift capacities up to 10,000 kg, cable lengths up to 10,000 m, electro-hydraulic drive, power ratings up to 120 hp and beyond;

- Hydraulic power units, hydraulic drive systems.

Learn more

Among the most advanced solutions are winches used in the oceanographic field, designed for dredging, coring, or lowering instruments at great depths. These systems can reach considerable pulleys, significant cable lengths, and sufficient power to support scientific work on complex seabeds. Hydraulic solutions include power packs and drive systems designed to ensure smooth, stable, and safe control of operations.

Construction and mechanical processing

- Execution of parts, equipment and complexes onour projectand todrawing;

- mechanical machining, turning, boring, wheel gear cutting.

Learn more

Mechanical machining includes the production of parts, equipment, and assemblies based on both in-house designs and customer drawings. Turning, boring, and gear cutting are performed with precision, using machinery and procedures that ensure tolerances appropriate to industry requirements. The company manages both single-part and batch production, ensuring consistent and repeatable results.

Lifting tools

- Design and construction of lifting equipment, lifting beams, under-hook equipment;

- CE marking.

Learn more

The design and construction of lifting equipment includes spreader bars, underhooks, and components dedicated to industrial handling. Each piece of equipment is manufactured in compliance with current regulations, with CE marking and technical inspections to ensure suitability and safety. The design phase takes into account the conditions of use and specific needs, ensuring stability and precision during operations.

Electrowelded constructions

- Design and construction of steel, stainless steel, and aluminum structures for special industrial applications.

- Structures, frames, etc.;

- Sheet metal working, cutting, bending, plasma cutting;

- Electrode, MIG, MAG and TIG welding;

- Approved procedures.

Learn more

Welded steel, stainless steel, and aluminum constructions are another area of expertise. The company creates frames, structures, and specialty metalwork using certified cutting, bending, and welding processes. The choice of materials and welding methods meets the criteria of strength, durability, and safety, essential for industrial environments that require continuous use.

Technology, materials and process monitoring

Continuous monitoring of production processes ensures high quality standards and verifies compliance with the technical specifications defined during the design phase. Monitoring activities include inspections, functional tests, and structural checks to ensure the final product fully meets operational requirements. The use of suitable materials and certified manufacturing techniques is essential for the construction of machinery and equipment designed for demanding working conditions.

Tailor-made mechanical solutions for highly specialized sectors

The ability to design and build custom solutions allows the company to provide solutions suited to specific contexts, with an approach focused on business continuity and safety. Thanks to the availability of qualified personnel and structured processes, each project is monitored from initial analysis to final production, ensuring complete management of the equipment's lifecycle.

Do you need to build machinery and mechanical equipment?

Request a quote for the construction of machinery and mechanical equipment in Trieste and call now for more information.

FAQ

What products are manufactured at Officine Meccaniche Vidali?

The company manufactures lifting machines, winches, mechanical equipment, electro-welded metalwork, and components based on designs or drawings.

Is it possible to request customized mechanical products?

Yes, production includes unique pieces and batches developed based on specific technical needs.

Are the winches designed for scientific activities?

Yes, some models are intended for oceanographic use, with technical specifications suitable for great depths and complex working conditions.

What materials are used in welded construction?

Depending on the application, steel, stainless steel and aluminium are used, processed using certified processes.

How is the design phase managed?

The design is based on functional analysis, technical definition of the equipment, and constant monitoring during construction.